Due to the dynamic nature of truck dumpers, regular greasing of all pivot and rotational parts is critical for sustained and safe operation. Failure to regularly maintain grease locations can cause premature failure in bearings and pins. This can result in higher maintenance costs as well as damage to the tipper which may create a sub-optimal and/or unsafe operating environment.

Grease Type

A mineral oil based grease with lithium soap and EP additives should be used on all grease locations on a truck dumper. Consult your grease supplier for suitable replacements if other environmental factors such as food grade, high temp, or other factors are needed.

How Often to Grease

Monthly greasing of all components listed below is recommended, with exception on service legs. Service legs may be greased quarterly due to their less frequent use. More frequent greasing may be required due to high use or weather/operating conditions.

Grease Location

A-Frame Bearings and Cylinder Top Pins

A-frame bearings and top pins should be greased monthly. Grease port extensions may be used to assist with ease of access. Each a-frame bearing has (1) one grease zerk. The bearings are made in matching pairs so grease zerks should be on the same side. There are no grease zerks on the cylinder pin eye or on the top pin.

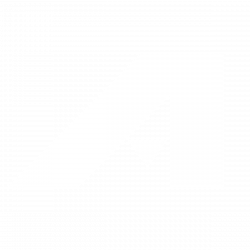

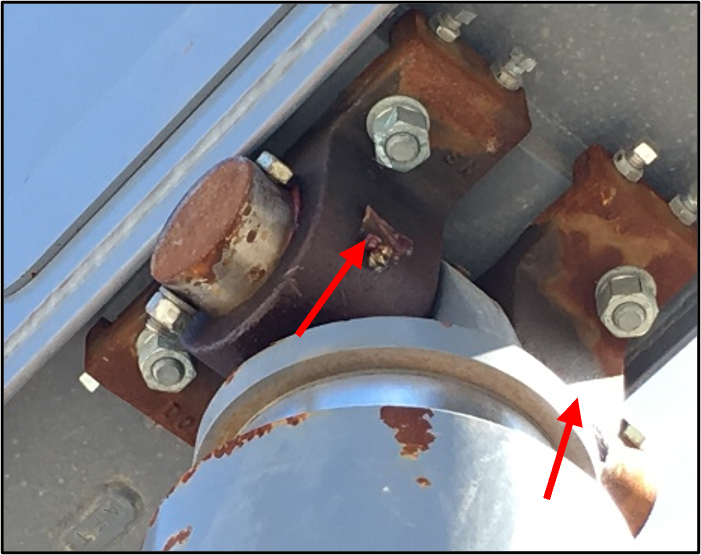

Main Pivot Bearings and Pins

Main pivot bearings and pins should be greased monthly, or more frequently for high use equipment (6+ hours per day). Pivot pins have grease grooves to allow the grease to flow evenly around the pin. Pivot bearings will have 1-3 zerks depending on the style and specific part.

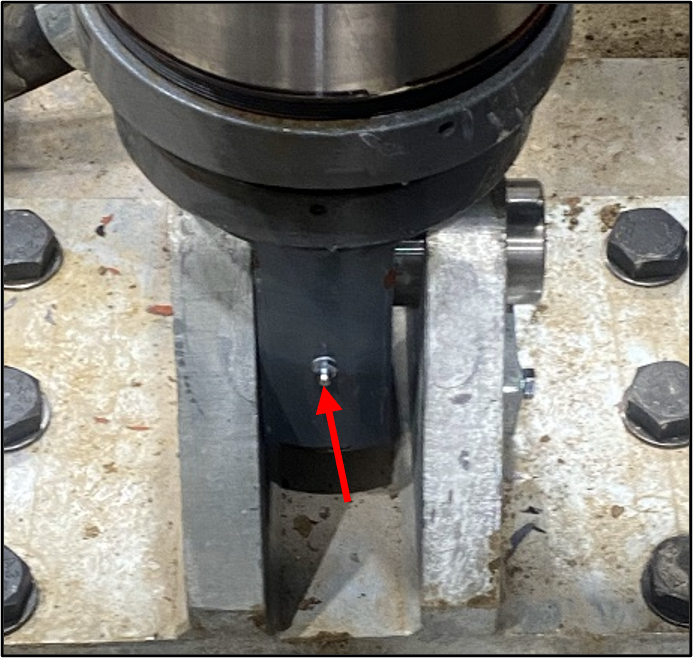

Cylinder Base Bearings and Bottom Pins

Most cylinder bases will have the grease zerk on the pin. Cylinder bases and bottom pins should be greased monthly.

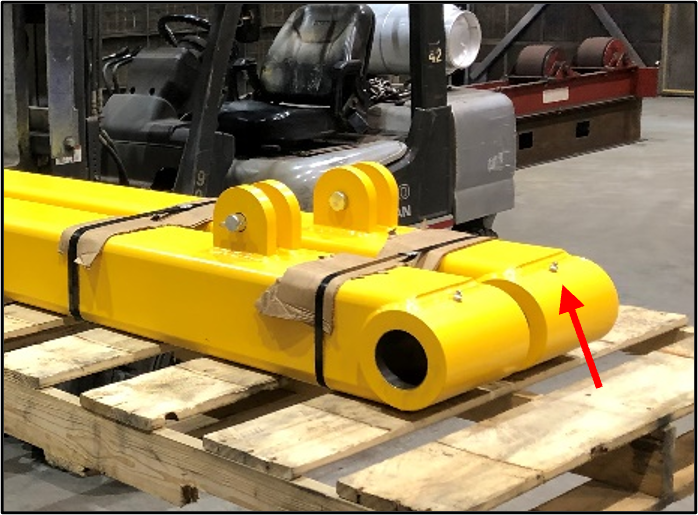

Inverted Cylinders and Trunnions

Inverted cylinders will have one grease zerk.

Toll Gate Cylinders

Backstop cylinders, including those used on toll gate style backstops, should be greased monthly or more frequently depending on use. Due to the limited rotational range of these cylinders, the pins should be rotated after greasing.

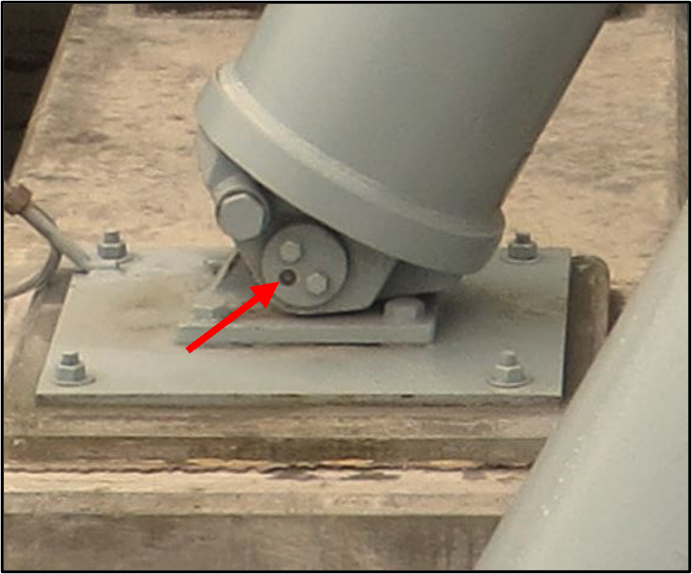

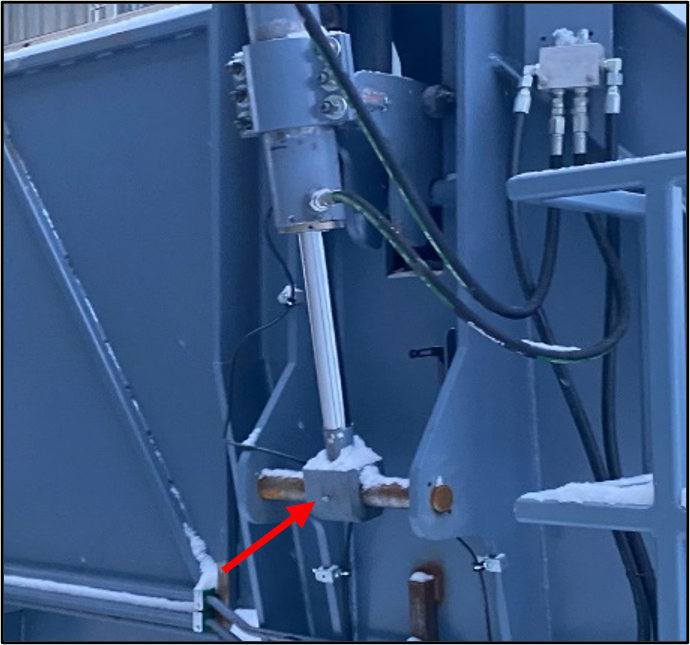

Service Legs

Service legs may be greased quarterly as they are only used for maintenance. Service legs will have a grease zerk on the bottom of each leg (top photo), and a ratchet binder (bottom photo). Zerk locations may vary on older models.

Summary

Regular greasing and maintenance is a critical step in the operation of truck dumpers. The information in this article provides a good basis for maintenance and care of your Airoflex truck dumper. Refer to the monthly, quarterly, and yearly maintenance schedules for in-depth information or contact the Airoflex team for assistance.

Maintenance Sheets

Click to download the monthly, quarterly, or yearly maintenance schedules.